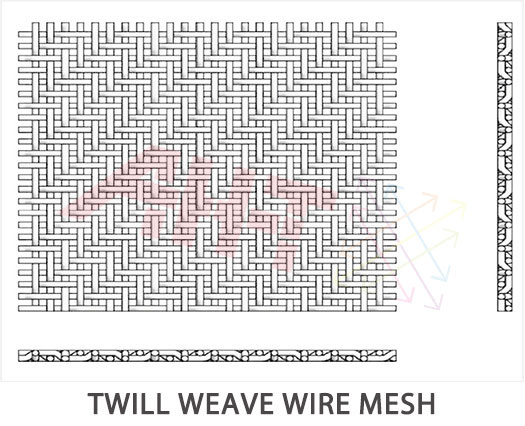

Twill Weave Wire Mesh

The twill wire mesh is made by alternately passing each weft thread through two warp threads. The pattern is interlaced on the continuous warp threads, presenting a parallel diagonal appearance. The mesh holes are small and uniform, with strong bearing capacity, high filtration density, and the ability to withstand greater loads and finer filtration. It is commonly used in filtration, screening, decoration and other precision applications.

Twill Weave Wire Mesh Features and Advantages

Fine filtration density

The aperture gap of twill weave wire mesh between the warp wire and weft wire are small, the structure is tight, the filtration performance is good, the filtration density is fine, and the small particles and impurities can be screened and filtered;Strong tensile strength

Because of its high structural density and unique weaving method, the twill weave wire mesh has high tensile strength and stability;

Because of its compact structure and high strength, twill weave wire mesh usually has better wear resistance and long service life;

Because of directivity and texture, good elasticity and strong load capacity, the twill weave wire mesh can be used in a variety of application scenarios.

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;Different metal materials can be customized according to customer needs.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom twill weave wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of twill weave wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System CertificationAuthorized Economic operator

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Twill Weave Wire Mesh Applications

Twill weave wire mesh is a versatile and durable material that can be used for a variety of different applications. Due to its high tensile strength, corrosion resistance, and temperature resistance. It is commonly used in industries of automotive, aerospace, chemical, and food processing etc, for filtration, separation, reinforcement, protection.

| Hatong Twill Weave Wire Mesh of Specification | |||

Meshes per linear inch | Wire Diameter | Mesh Opening | Open Area |

mm | mm | % | |

150×150 | 0.07 | 0.0993 | 34.4 |

165×165 | 0.058 | 0.0959 | 38.83 |

180×180 | 0.058 | 0.0831 | 34.69 |

200×200 | 0.058 | 0.069 | 29.52 |

225×225 | 0.05 | 0.069 | 33.62 |

235×235 | 0.045 | 0.0631 | 34.07 |

250×250 | 0.04 | 0.0616 | 36.76 |

270×270 | 0.04 | 0.0541 | 33.05 |

280×280 | 0.04 | 0.0507 | 31.25 |

300×300 | 0.035 | 0.0497 | 34.43 |

300×300 | 0.038 | 0.0467 | 30.4 |

300×300 | 0.04 | 0.0447 | 27.85 |

315×315 | 0.035 | 0.0456 | 32.01 |

325×325 | 0.035 | 0.0432 | 30.52 |

350×350 | 0.035 | 0.0376 | 26.82 |

350×350 | 0.03 | 0.0426 | 34.43 |

363×363 | 0.03 | 0.04 | 32.65 |

385×385 | 0.03 | 0.0377 | 31.01 |

400×400 | 0.025 | 0.0385 | 36.76 |

400×400 | 0.028 | 0.0355 | 31.25 |

400×400 | 0.03 | 0.0335 | 27.83 |

420×420 | 0.03 | 0.0302 | 25.17 |

450×450 | 0.025 | 0.0314 | 31 |

500×500 | 0.025 | 0.0258 | 25.79 |

510×510 | 0.025 | 0.0248 | 24.8 |

530×530 | 0.024 | 0.0239 | 24.9 |

635×635 | 0.018 | 0.022 | 30.25 |

635×635 | 0.02 | 0.02 | 25 |

800×800 | 0.016 | 0.0164 | 25.62 |