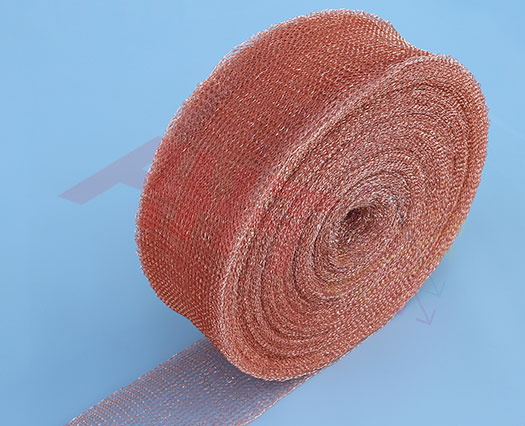

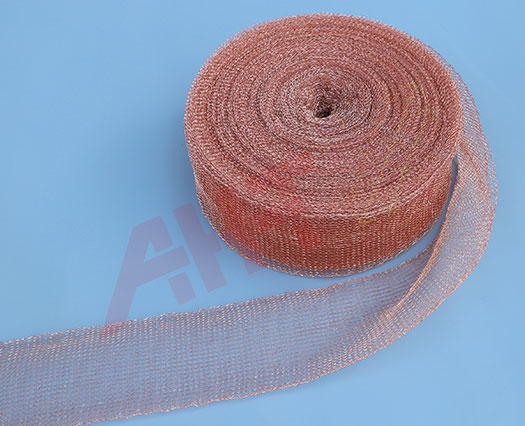

Copper Knitted Mesh

The copper knitted mesh is made by hooking together copper wire strands with a purity of up to 99.99%. These copper wires are woven into tubular shapes, then flattened into continuous strips and rolled up for packaging. Compared to stainless steel woven mesh, copper knitted mesh is softer, more corrosion-resistant, but more susceptible to erosion by oxidants (such as nitric acid, chlorine, iron, fluorides, and amino acid compounds). The alloy metal knitting fabric machine of Hatong was designed and independently developed by the research and development department. It is made by hooking together without oil. It has the characteristics of uniform pores, smooth surface, high thermal conductivity, high electrical conductivity, and good ductility. It is widely used in radio frequency interference (RFI) shielding, Falzer cages, roof heating and air conditioning, and many electrical applications.

Copper Knitted Mesh Features and Advantages

Clean mesh

Our factory introduces advanced technology, using oil-free weaving, the production of copper knitted mesh has the characteristics of clean mesh and uniform mesh;

Corrosion resistance and high temperature resistance

Excellent performance in seawater and other highly corrosive media. It can maintain good corrosion resistance in a variety of acids, alkalis, salt solutions and organic acids, and its smelting point is as high as 1083℃. This feature enables copper vapor-liquid mesh to maintain stable performance in high temperature environments and is suitable for various high temperature industrial processes;

Electrical conductivity, thermal conductivity

Copper as an excellent conductive material, its electrical conductivity mainly from its internal free electrons. In the metal lattice, these free electrons can move freely to form a current, which promotes the copper knitted mesh to have high-quality electrical and thermal conductivity;

Easy to process

Copper knitted mesh because of its unique processing technology, so that it has strong and flexible characteristics, easy to cut, bending, stretching and other industrial processing.

Copper Knitted Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom copper knitted mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of copper knitted mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Copper Knitted Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Copper Knitted Mesh Packaging

Inner paper tube & Carton box & Plywood case

Copper Knitted Mesh Applications

Copper knitted wire mesh is widely used in a range of industrial, commercial, and household applications. Some of the typical uses of copper knitted wire mesh include:

- Filtration: Copper knitted wire mesh is commonly used as a filtering medium in various industries, including petrochemical, pharmaceutical, and food processing, to remove impurities from liquids and gases.

- Sealing: Copper knitted wire mesh is highly compressible and flexible, making it an ideal material for sealing applications in automotive, aerospace, and other industries, where it is used to prevent the leakage of fluids and gases.

- Catalysis: Copper knitted wire mesh is also used as a catalytic converter substrate in automotive exhaust systems, where it helps to reduce harmful emissions and improve fuel efficiency.

- EMI shielding: Copper knitted wire mesh is an excellent electromagnetic interference (EMI) and radio frequency interference (RFI) shielding material, making it ideal for use in electronic devices, shielding rooms, and other applications where electromagnetic interference needs to be minimized.

Copper Knitted Mesh Specifications

| AHT/Hatong Copper Knitted Mesh of Specification | ||||

Specification of Round Wire Knitted Mesh | ||||

Type | Wire Diameter(mm) | Width (mm) | Number of Stitches Per cm on Length | Number of Stitches Per cm Across Lay Flat |

Fine Mesh | 0.08-0.18 | 6-300 | 3.5 | 4.4 |

Medium-Fine Mesh | 0.16 | 40-600 | 2.4 | 3.5 |

Standard Mesh | 0.08-0.35 | 30-1000 | 1.6 | 1.9 |

Coarse Mesh | 0.25-0.40 | 30-1000 | 1.6 | 0.74 |

Super Coarse Mesh | 0.4-0.5 | 100-350 | 0.5 | 0.5 |

Specification of Fat Wire Knitted Mesh | ||||

Wire Diameter (mm) | Mesh Opening/Loop Size(mm) | Number of Needles | Maximum Width (mm) | Minimum Width (mm) |

0.1×0.3 | 2×4 | 36 | 60 | 55 |

0.1×0.3 | 4.5×4,2.5×4 | 34 | 150 | 100 |

0.1×0.4 | 4.5×5.5,2.5×5.5 | 40 | 150 | 120 |

0.1×0.4 | 4×3.5,2.5×3.5 | 56 | 205 | 180 |

0.1×0.4 | 4×4,3×4 | 65 | 260 | 240 |

0.2×0.4 | 5.2×3.5,3×3.5 | 94 | 420 | 380 |

0.2×0.4 | 7.5×5,5×5 | 102 | 565 | 490 |

0.2×0.5 | 5×4,2.5×4 | 128 | 560 | 470 |