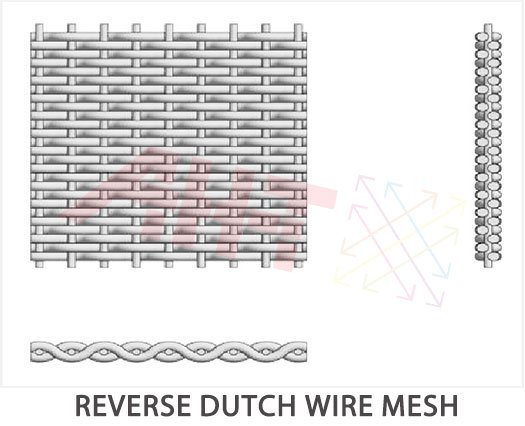

Reverse Dutch Weave Wire Mesh

The reverse dutch weave wire mesh is a metal wire mesh with closely woven warp threads and coarser weft threads. This unique weaving method gives the filter cloth high strength and filtration performance. The shape and position of the mesh holes facilitate particle retention and promote the formation of the filter cake. Its distinctive pattern design enables good air and light circulation, and enhances the strength of the metal-woven metal wire mesh, prolonging its service life, making it an ideal choice for applications with high ventilation or light transmission requirements.

Reverse Dutch Weave Wire Mesh Features and Advantages

Reverse dutch weave wire mesh is a special textile technology with thinner warp wire and thicker weft wire, which is the exact opposite of standard dutch weave wire mesh. The mesh is uniform, the mesh surface is flat, the warp wire is fine, the filter surface is wide, and the filter performance is good.

Reverse dutch weave wire mesh is very strong, with a high degree of durability and load strength, suitable for applications requiring fine filtration and high strength.

Our factory will strictly control the selection of raw materials, select high-quality raw materials with high temperature, and ensure the application of severe industrial environment in the production and processing process.

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;Different metal materials can be customized according to customer needs.

Reverse Dutch Weave Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom reverse dutch weave wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of reverse dutch weave wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System CertificationReverse Dutch Weave Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Reverse dutch weave wire mesh is widely used in many industries due to its excellent filtration and strength properties.

Filtration: Reverse dutch weave wire mesh is commonly used in chemical and pharmaceutical industries for filtering liquids and gases. This includes food and beverage filtering, oil and gas filtering, and water treatment filtering.

| AHT/Hatong Reverse Dutch Weave Wire Mesh of Specification | ||||||||

Hatong | Mesh | Wire Diameter ( um ) | Micron Retention ( um) | Porosity | Weight (kg/㎡) | Cloth | ||

Warp | Weft | Nominal | Absolute | |||||

RPD 40 | 280×60-70 | 90 | 200 | 40 | 54-60 | 56 | 1.34-1.55 | .38-.40 |

RPD 60 | 175×40-50 | 150 | 300 | 60 | 65-72 | 55 | 2.1-2.40 | .57-.60 |

RPD 80 | 130×30-35 | 200 | 380 | 80 | 95-105 | 57 | 2.7-3.10 | .77-.80 |

RPD 85 | 175×37 | - | - | 85 | 100-106 | 54 | 2.10 | .57 |

RPD 90 | 170×40 | - | - | 90 | 106-118 | 54 | 2.10 | .57 |

RPD 125 | 260×40 | - | - | 125 | 112-125 | 54 | 2.25 | .62 |

RPD 400 | 84×14 | - | - | - | 450-530 | 62 | 3.50 | 1.15 |