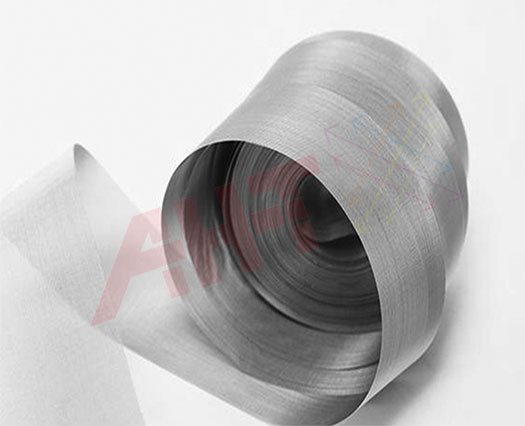

Nickel Wire Mesh

The nickel wire mesh is made of high-quality nickel wire with a purity of no less than 99%. Due to its excellent chemical and physical properties, the nickel mesh has good electrical conductivity, thermal conductivity, ductility and acid-base resistance. It plays a very important role in the fields of electrolytic hydrogen production, new energy and fuel cell technology, and is commonly used in alkali production, chemical filtration, aerospace engineering, alkali treatment, drug processing, and for screening and separation of gases and liquids in strong acid and strong base media.

Nickel Wire Mesh Features and Advantages

Excellent electrical conductivity

Nickel is a good conductive material, so nickel wire mesh has excellent conductive properties. This makes nickel mesh in electronics, communications and other fields have a wide range of applications, such as the production of electromagnetic shielding materials, conductive cloth and so on.

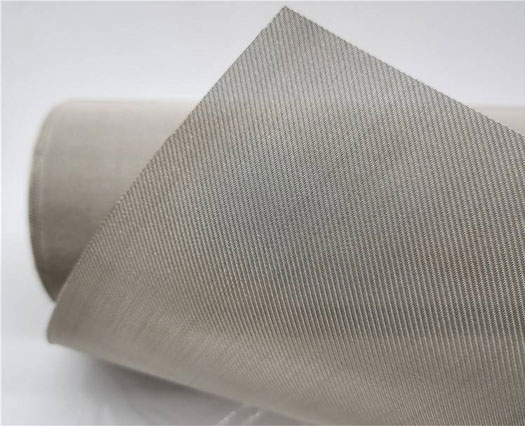

High temperature resistance

Nickel wire mesh has a high melting point and high temperature resistance, and can maintain stable physical and chemical properties in high temperature environments. This makes the nickel mesh in chemical, petroleum and other fields of high temperature reactor and catalyst carrier have a unique advantage.

Corrosion resistance

Nickel wire mesh has good corrosion resistance to a variety of chemical media, such as acid, alkali, salt and so on. This makes the nickel mesh in chemical, pharmaceutical and other fields of equipment manufacturing and pipeline connection have a wide range of applications.

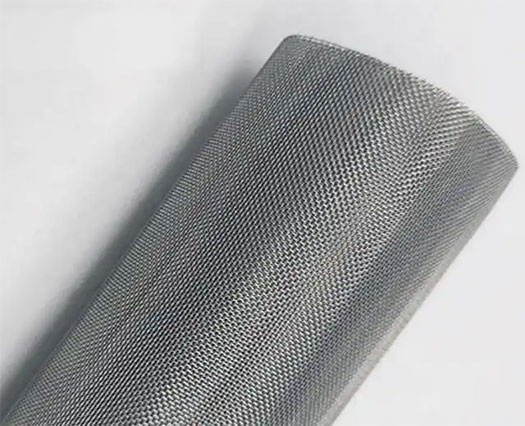

Strong load capacity

Nickel wire mesh has high tensile strength and fatigue resistance, and can withstand large tensile and compressive forces. This makes nickel mesh in the manufacture of filters, screens, protective mesh have a wide range of applications.

Nickel Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom nickel wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of nickel wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Nickel Wire Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Nickel Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Nickel Wire Mesh Applications

Nickel wire mesh is mainly used in petroleum, chemical, aerospace and other industries.

Nickel Wire Mesh Specifications

| AHT/Hatong Nickel Wire Mesh of Specification | |||||||||||

Chemical Composition of Nickel | |||||||||||

Type | C(%) | Cu(%) | Fe(%) | Mn(%) | Ni(%) | S(%) | Si(%) | Co(%) | Cr(%) | Mg(%) | Ti(%) |

Nickel 200 | 0.015 | 0.25 | 0.40 | 0.35 | 99.0 | 0.01 | 0.35 | - | - | - | - |

Nickel 205 | 0.02 | 0.001 | 0.005 | 0.001 | 99.97 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

Nickel 270 | 0.15 | 0.15 | 0.20 | 0.35 | 99.0 | 0.008 | 0.15 | - | 0.01-0.05 | 0.01-0.08 | - |

Specification of Nickel 200 Woven Mesh | |||||||||||

Item | Mesh Count | Wire Diameter | Weave Type | Width Opening | Open Area | ||||||

NI200-1 | 8×8 | 0.0280 | Plain | 0.0970 | 60.20 | ||||||

NI200-2 | 10×10 | 0.0200 | Plain | 0.0800 | 64.00 | ||||||

NI200-3 | 12×12 | 0.0140 | Plain | 0.0693 | 69.20 | ||||||

NI200-4 | 16×16 | 0.0120 | Plain | 0.0505 | 65.30 | ||||||

NI200-5 | 16×16 | 0.0140 | Plain | 0.0485 | 60.20 | ||||||

NI200-6 | 20×20 | 0.0045 | Plain | 0.0455 | 82.80 | ||||||

NI200-7 | 20×20 | 0.0070 | Plain | 0.0430 | 74.00 | ||||||

NI200-8 | 20×20 | 0.0140 | Plain | 0.0360 | 51.80 | ||||||

NI200-9 | 25×25 | 0.0060 | Plain | 0.0190 | 57.80 | ||||||

NI200-10 | 26×26 | 0.0100 | Plain | 0.0285 | 54.80 | ||||||

NI200-11 | 30×30 | 0.0130 | Plain | 0.0203 | 37.20 | ||||||

NI200-12 | 40×40 | 0.0060 | Plain | 0.0190 | 57.80 | ||||||

NI200-13 | 40×40 | 0.0100 | Plain | 0.0150 | 36.00 | ||||||

NI200-14 | 50×50 | 0.0020 | Plain | 0.0180 | 81.00 | ||||||

NI200-15 | 60×60 | 0.0070 | Plain | 0.0097 | 33.60 | ||||||

NI200-16 | 60×60 | 0.0105 | Twill | 0.0062 | 13.70 | ||||||

NI200-17 | 60×60 | 0.0100 | Twill | 0.0057 | 11.60 | ||||||

NI200-18 | 70×70 | 0.0040 | Plain | 0.0103 | 51.80 | ||||||

NI200-19 | 70×70 | 0.0045 | Plain | 0.0098 | 46.90 | ||||||

NI200-20 | 70×70 | 0.0080 | Twill | 0.0063 | 19.40 | ||||||

NI200-21 | 80×80 | 0.0055 | Twill | 0.0070 | 31.40 | ||||||

NI200-22 | 85×70 | 0.0060 | Plain | 0.0000 | 28.40 | ||||||

NI200-23 | 100×100 | 0.0020 | Plain | 0.0080 | 64.00 | ||||||

NI200-24 | 100×100 | 0.0040 | Plain | 0.0060 | 36.00 | ||||||

NI200-25 | 100×100 | 0.0045 | Plain | 0.0060 | 30.30 | ||||||

NI200-26 | 200×200 | 0.0018 | Plain | 0.0032 | 41.00 | ||||||

Specification of Nickel 205 Woven Mesh | |||||||||||

Item | Mesh Count | Wire Diameter | Type Weave | Width Opening | Open Area | ||||||

NI205-1 | 60×60 | 0.0060 | Plain | 0.0107 | 41.00 | ||||||

Specification of Nickel 270 Woven Mesh | |||||||||||

Item | Mesh Count | Wire Diameter | Type Weave | Width Opening | Open Area | ||||||

NI270-1 | 50×50 | 0.0670 | Plain | 0.0133 | 44.2 | ||||||

NI270-2 | 60×60 | 0.0040 | Plain | 0.0127 | 57.8 | ||||||

NI270-3 | 60×60 | 0.0060 | Plain | 0.0107 | 41.0 | ||||||

NI270-4 | 60×60 | 0.0070 | Plain | 0.0097 | 33.6 | ||||||

NI270-5 | 75×75 | 0.0060 | Plain | 0.0073 | 30.3 | ||||||