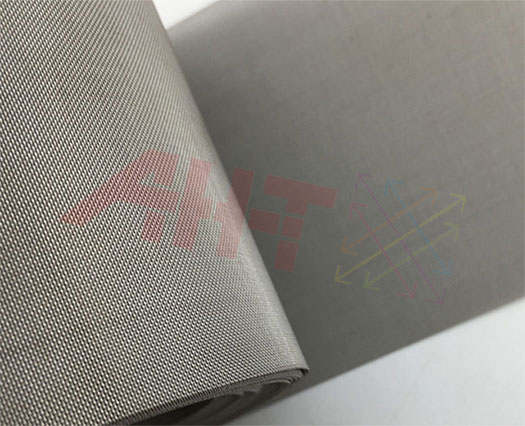

Monel Wire Mesh

The Monel wire mesh is made of Monel alloy wire (belonging to nickel-based alloy), and it is divided into Monel 400 and Monel K500. Monel 400 alloy is a unique and durable material mainly composed of copper and nickel. As a copper-nickel alloy, Monel 400 exhibits high strength and excellent corrosion resistance in various media such as seawater acidic and alkaline environments. Due to the addition of aluminum, the tensile strength and hardness of Monel K500 alloy are higher than those of Monel 400, and it is suitable for applications such as filtration, separation, screening and reinforcement. Monel wire mesh is a commonly used material in industries such as chemical processing, marine, aerospace, oil and gas, etc.

Monel Wire Mesh Features and Advantages

Resistance to static and erosion

Monel wire mesh has good corrosion resistance to high concentration acids such as sulfuric acid, hydrochloric acid and phosphoric acid, and can be used in seawater, chemical solvents, acidic media and other environments.

High temperature resistance

Monel wire mesh can withstand the temperature of up to 600℃, can still maintain stable performance under high temperature conditions, suitable for use in high temperature environment;

Stress corrosion resistance

Monel wire mesh has high tensile strength and high mechanical strength, which can effectively resist stress corrosion.

Good welding and processing properties

Monel wire mesh has good welding properties and cold working properties, easy to process and install.

Monel Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom Monel wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of Monel wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Monel Wire Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

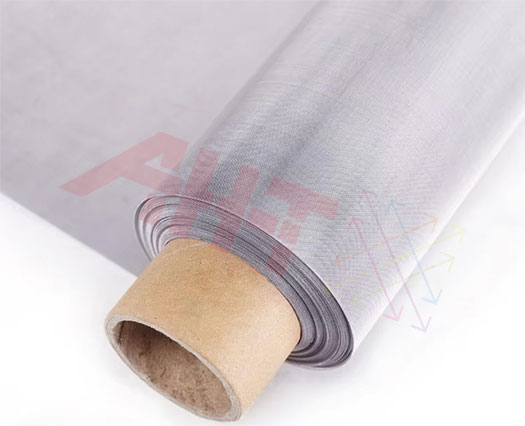

Monel Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Monel Wire Mesh Applications

Chemical processing: Monel wire mesh is highly resistant to corrosion and chemical attack, making it suitable for use in the chemical processing industry. It is used for filtration, separation, and as a catalyst support in processes involving corrosive chemicals.

Oil and Gas Industry: Monel wire mesh is utilized in the oi and gas industry for applications such as filtration, erosion control and protection against sand and other particulates in drilling and production equipment.

Electrical and Electronics: Monel wire mesh can be used in electrical and electronic applications where conductivity, durability, and resistance to corrosion are required. Examples include shielding, grounding, and antenna applications.

Monel Wire Mesh Specifications

| AHT/Hatong Monel Wire Mesh of Specification | |||||||||

Chemical Composition of Monel | |||||||||

Type | C(%) | Mn(%) | Si(%) | S(%) | Cu(%) | Fe(%) | Ni(%) | AI (%) | Ti (%) |

Monel 400 | ≤0.30 | ≤2.0 | ≤0.5 | ≤0.024 | 28-34 | ≤2.5 | ≥63.0 | - | - |

Monel K500 | ≤0.25 | ≤1.5 | ≤0.5 | ≤0.01 | 27-33 | ≤2.0 | ≥63.0 | 2.3-3.15 | 0.35-0.85 |

Item | Mesh (line/inch) | Wire diameter (inch) | Opening width (inches) | Open area (%) | |||||

Monel alloy-1 | 8×8 | 0.0280 | 0.0970 | 60.2 | |||||

Monel alloy-2 | 10×10 | 0.0250 | 0.0750 | 56.3 | |||||

Monel alloy-3 | 12×12 | 0.0230 | 0.0600 | 51.8 | |||||

Monel alloy-4 | 20×20 | 0.0160 | 0.0340 | 46.2 | |||||

Monel alloy-5 | 30×30 | 0.0130 | 0.0203 | 37.2 | |||||

Monel alloy-6 | 40×40 | 0.0100 | 0.0150 | 36.0 | |||||

Monel alloy-7 | 60×60 | 0.0072 | 0.0090 | 30.5 | |||||

Monel alloy-8 | 80×80 | 0.0055 | 0.0070 | 31.4 | |||||

Monel alloy-9 | 100×100 | 0.0045 | 0.0060 | 30.3 | |||||

Monel alloy-10 | 120×120 | 0.0036 | 0.0047 | 32.3 | |||||

Monel alloy-11 | 150×150 | 0.0026 | 0.0041 | 37.2 | |||||

Monel alloy-12 | 200×200 | 0.0021 | 0.0533 | 33.6 | |||||