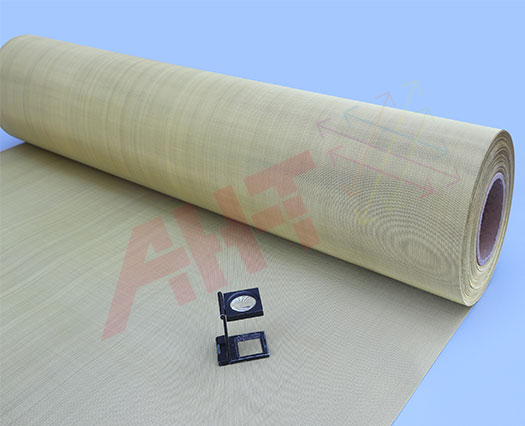

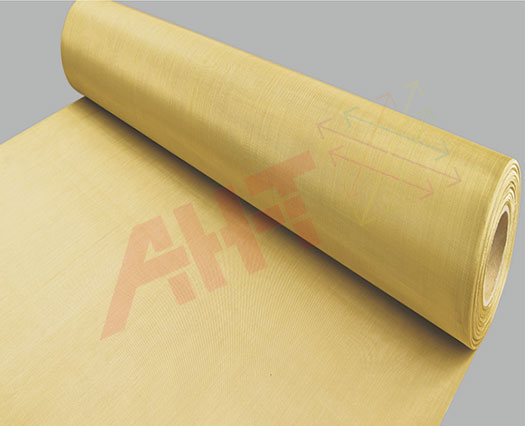

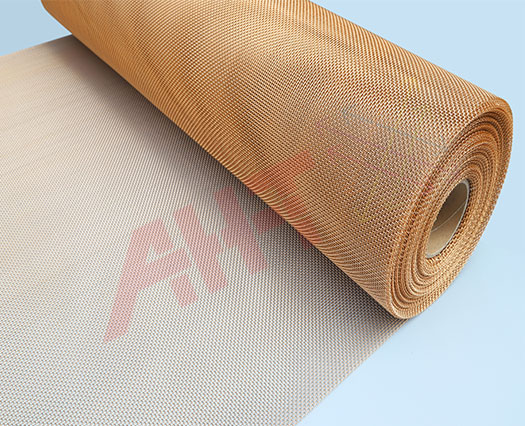

Brass Wire Mesh

The brass wire mesh is made by weaving high-quality brass wires with good extensibility and malleability. It contains 65% copper and 35% zinc, has a bright color, a smooth surface, and is easy to cut, shape and weld. The common weaving patterns are plain weave and twill weave, which have superior wear resistance, corrosion resistance and lower conductivity. It is mainly used for filtering and separating metal powder in pharmaceuticals, ceramic printing, electromagnetic shielding, etc.

Brass Wire Mesh Features and Advantages

Non-magnetic: brass wire mesh has high quality non-magnetic, ensuring that there will be no magnetic induction in the magnetic field and will not be affected by magnetic force.

Brass Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom brass wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of brass wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Brass Wire Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Brass Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Brass Wire Mesh Applications

It can be used as shielding screens in the circuits, laboratories and computer rooms. Shielding effectiveness calculator also illustrates the difference between copper wire meshes at various radio frequencies. In addition, it can be installed on buildings for sound insulation or is fabricated into polymer extruder screen for polymer filtration.

Brass Wire Mesh Specifications

| AHT/Hatong Brass Wire Mesh of Specification | ||||

Item | Mesh (line/inch) | Wire diameter (inch) | Opening width (inches) | Open area (%) |

Brass wire-1 | 2×2 | 0.0630 | 0.437 | 76.4 |

Brass wire-2 | 3×3 | 0.0630 | 0.270 | 65.6 |

Brass wire-3 | 4×4 | 0.0630 | 0.187 | 56.0 |

Brass wire-4 | 4×4 | 0.0470 | 0.203 | 65.9 |

Brass wire-5 | 6×6 | 0.0350 | 0.132 | 62.7 |

Brass wire-6 | 8×8 | 0.0280 | 0.097 | 60.2 |

Brass wire-7 | 10×10 | 0.0250 | 0.075 | 56.3 |

Brass wire-8 | 12×12 | 0.0230 | 0.060 | 51.8 |

Brass wire-9 | 14×14 | 0.0200 | 0.051 | 51.0 |

Brass wire-10 | 16×16 | 0.0180 | 0.045 | 50.7 |

Brass wire-11 | 18×18 | 0.0170 | 0.039 | 48.3 |

Brass wire-12 | 20×20 | 0.0160 | 0.034 | 46.2 |

Brass wire-13 | 24×24 | 0.0140 | 0.028 | 44.2 |

Brass wire-14 | 30×30 | 0.0130 | 0.020 | 37.1 |

Brass wire-15 | 40×40 | 0.0100 | 0.015 | 36.0 |

Brass wire-16 | 50×50 | 0.0090 | 0.011 | 30.3 |

Brass wire-17 | 60×60 | 0.0075 | 0.009 | 30.5 |

Brass wire-18 | 80×80 | 0.0055 | 0.007 | 31.4 |

Brass wire-19 | 100×100 | 0.0045 | 0.006 | 30.3 |