Quality Control

Hatong has obtained certifications such as ISO9001 and ISO45001, and has established a complete quality control system. To ensure that our metal woven wire mesh and stainless steel filter elements and other products meet the different needs of customers, from raw material procurement to final delivery, we have equipped professional quality inspectors and advanced testing equipment for strict inspections.

Raw Material

Our quality control system begins with the selection of reliable suppliers for raw materials. We conduct comprehensive tests and analyses to ensure that the raw materials meet the quality and performance standards.

Key Parameter Management During Production

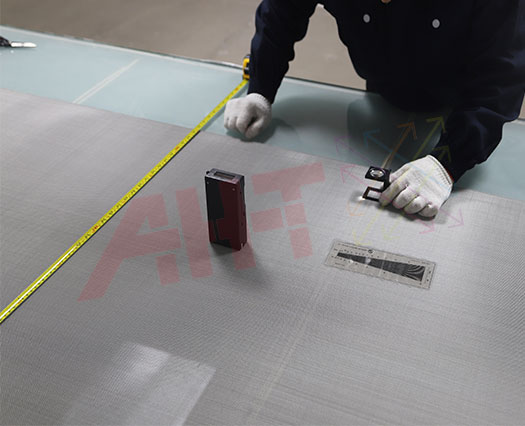

During the production process, experienced technicians will conduct regular inspections and tests (including tensile strength and dimensional accuracy) to ensure that the woven wire mesh and stainless steel filter elements, among other products, meet the required standards.

QC System

Our QC system is provided with advanced testing devices, skillful operators and strict QC technical assessors.

Packaging

Our various products will be packaged in different ways to prevent damage to the goods during transportation.

Transportation System

We have long-term cooperation with reliable and trustworthy freight forwarders to ensure that our woven wire mesh and stainless steel filter elements and other products can be delivered safely and efficiently. At the same time, we will track the logistics information of each batch of goods in real time and inform the customers simultaneously to ensure the transparency of the logistics process.