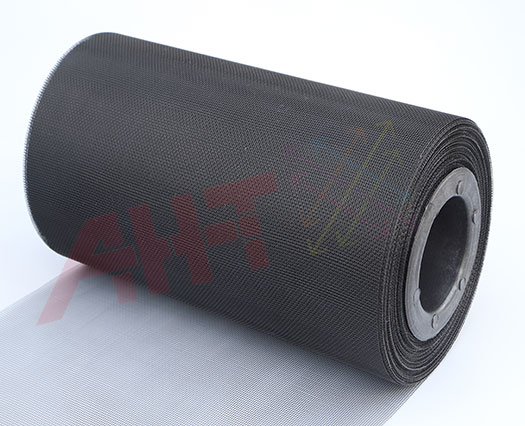

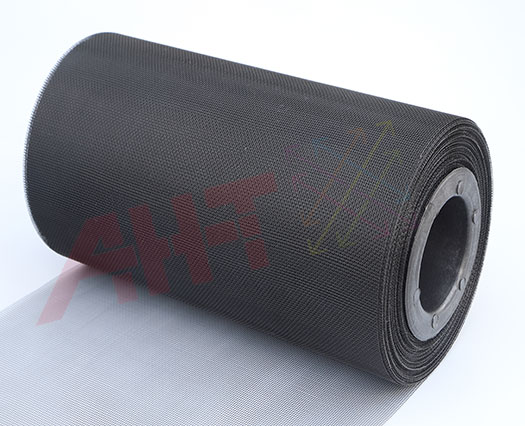

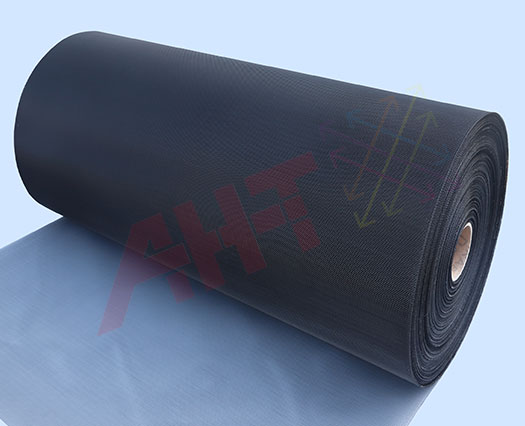

Epoxy Coated Wire Mesh

The epoxy coated wire mesh is made by weaving a single metal wire (with different diameters, lengths and patterns depending on the application) into a mesh pattern. The surface of the mesh is coated with epoxy resin and polyamine curing agent to provide corrosion resistance. When the epoxy coating is fully cured, the resulting product is a durable and hard plastic coating. Common materials used for epoxy coated wire mesh include stainless steel, low-carbon steel aluminum alloy, epoxy powder. The common color is black, but we can also provide colors according to your requirements. Epoxy coated wire mesh are important materials in construction projects. They can provide high load-bearing capacity and strength for concrete or floors and various foundation structures.

Epoxy Coated Wire Mesh Features and Advantages

Strong adhesion

The epoxy coating of epoxy coated wire mesh has excellent adhesion to metal, cement, glass fiber reinforced plastic and other materials, which can ensure that the coating is firmly attached to the substrate and is not easy to fall of.

Wear and corrosion resistant environment

Epoxy coated wire mesh has good wear resistance and corrosion resistance, can resist the erosion of chemical substances, suitable for a variety of harsh;

Good stability

Epoxy coated wire mesh paint film is tough, impact resistance, wear resistance, toughness and bending resistance, which can provide good protection effect for the screen and improve the service life;

Easy to use

Epoxy coated wire mesh coating can be cured into film at normal temperature, which is not affected by the site environment, easy to use and simple to operate.

Epoxy Coated Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom epoxy coated wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of epoxy coated wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Epoxy Coated Wire Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Epoxy Coated Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Epoxy Coated Wire Mesh Applications

Epoxy coated wire mesh is widely used. In many cases, it is used as part of large structures, such as frames, cages and other structural components. It can also be used as filters or screens in filtration and screening applications. It is very common in applications such as aerospace, automotive, energy, and food and beverage industries. Epoxy coated wire mesh is also used in chemical processing, for example, for the production of adhesives, resins and coatings.

| AHT/Hatong Epoxy Coated Wire Mesh of Specification | |||

STYLE | W×L | PACKAGED(BUNDLES) | STD.T/L QTY. |

6×6-W1.4/W1.4 | 8' ×20' | 100 Sheets | 1400 |

6×6-W1.4/W1.4 | 8' ×15' | 100 Sheets | 2000 |

6×6-W1.4/W1.4 | 8' ×12' 6" | 100 Sheets | 2400 |

6×6-W1.4/W1.4 | 5' ×10' | 100 Sheets | 3500 |

6×6-D2.1/D2.1 | 8' ×20' | 50 Sheets | 1050 |

6×6-D2.1/D2.1 | 8' ×15' | 50 Sheets | 1400 |

6×6-D2.1/D2.1 | 8' ×12' 6" | 50 Sheets | 1700 |

6×6-D2.1/D2.1 | 5' ×10' | 100 Sheets | 3000 |

6×6-D2.9/D2.9 | 8' ×20' | 50 Sheets | 750 |

6×6-D2.9/D2.9 | 8' ×15' | 50 Sheets | 1000 |

6×6-D2.9/D2.9 | 8' ×12' 6" | 50 Sheets | 1200 |

6×6-D2.9/D2.9 | 5' ×10' | 100 Sheets | 2000 |

6×6-D4/D4 | 8' ×20' | 50 Sheets | 525 |

6×6-D4/D4 | 8' ×15' | 50 Sheets | 700 |

6×6-D4/D4 | 8' ×12' 6" | 50 Sheets | 850 |

6×6-D4/D4 | 5' ×10' | 50 Sheets | 1500 |

4×4-D2.9/D2.9 | 8' ×20' | 50 Sheets | 500 |

4×4-D2.9/D2.9 | 8' ×15' | 50 Sheets | 650 |

4×4-D2.9/D2.9 | 8' ×12' 6" | 50 Sheets | 800 |

4×4-D2.9/D2.9 | 5' ×10' | 100 Sheets | 1600 |

4×4-D4/D4 | 8' ×20' | 25 Sheets | 350 |

4×4-D4/D4 | 8' ×15' | 25 Sheets | 475 |

4×4-D4/D4 | 8' ×12' 6" | 50 Sheets | 550 |

4×4-D4/D4 | 5' ×10' | 50 Sheets | 1150 |

| Rolls | |||

STYLE | W×L | PACKAGED(BUNDLES) | STD.T/L QTY. |

6×6- W1.4/W1.4 | 5' ×150' | 18 Rolls | 324 |

6×6- W1.4/W1.4 | 6' ×150' | 17 Rolls | 272 |

6×6- W1.4/W1.4 | 5' ×200' | 15 or 12 & 7 Rolls | 240 |

6×6- D2.1/D2.1 | 5' ×150' | 15 Rolls | 225 |

6×6- D2.9/D2.9 | 5' ×150' | 12 & 8 Rolls | 160 |