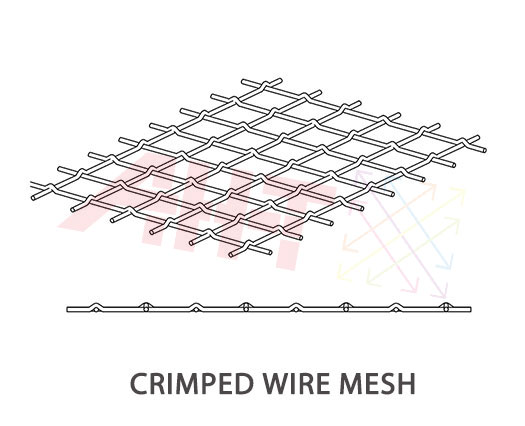

Crimped Wire Mesh

The crimped wire mesh is a metal wire mesh made of interlocked or nested reed metal wires. During the reed weaving process, the crimped wire mesh is bent at specific intervals, forming ridge-like or wave-like patterns within the mesh holes to maintain an accurate mesh structure. This crimped weaving technique enhances the rigidity and strength of the mesh holes, and is suitable for various applications.

Crimped Wire Mesh Features and Advantages

Rigidity and durability

Made of high-quality raw materials and carefully woven, it has high tensile strength and wear resistance, and can withstand greater pressure and weight without deformation or damage.

Adopting advanced weaving methods makes the mesh structure very stable and not easily deformed. The surface pattern design increases friction, can effectively prevent sliding and displacement when carrying heavy objects, and ensuring safe use.

Because of its unique weaving method, crimped wire mesh can maintain good air circulation even if it is compressed by heavy objects, so that the object will not deteriorate due to humidity and mold.

Because the mesh of braided ginning net is uniform and regular, the target particles can be screened effectively and the screening efficiency can be improved.

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;Different metal materials can be customized according to customer needs.

Crimped Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom crimped wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of crimped wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Crimped Wire Mesh Quality Control

Authorized Economic Operator

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Crimped Wire Mesh Applications

1. Screening and filtration: Crimped weave mesh is often used for screening or filtering applications, such as in vibrating screens, sieves, or equipment used in the mining, quarrying, or aggregate industries. The crimped pattern helps to improve the efficiency of screening and filtration processes.

2. Architectural and decorative purposes: Crimped weave mesh can be used to create aesthetic and functional architectural elements, such as facades, room dividers, or decorative screens. The unique texture and pattern of the mesh provide visual interest and can be customized to meet specific design requirements.

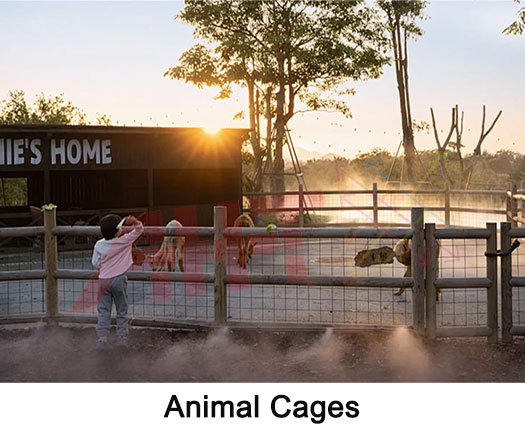

3. Security and fencing: The strength and rigidity of crimped weave mesh make it suitable for security applications, such as window or door screens, perimeter fences, or animal enclosures. The mesh provides a barrier while still allowing visibility and airflow.

4. Reinforcement: Crimped weave mesh can be used to reinforce concrete structures, such as walls or pavements, by adding strength and preventing cracks. The mesh is embedded within the concrete to provide structural support.

6. Pest control: Crimped weave mesh can be used to keep out insects and pests while allowing ventilation. It is commonly used in agriculture, horticulture, or food processing facilities.

Crimped Wire Mesh Specifications

| AHT/Hatong Crimped Wire Mesh of Specification | |||||

Wire diameter:6#-14# | |||||

Mesh size:3/8"-2 1/2" | |||||

Aperture | 6# | 8# | 10# | 12# | 14# |

3/8" |

|

|

|

| ☑ |

| 1/2" |

|

|

| ☑ | ☑ |

5/8* |

| ☑ | ☑ | ☑ | ☑ |

| 3/4" |

| ☑ | ☑ | ☑ | ☑ |

| 1 |

|

| ☑ | ☑ | ☑ |

1 1/4" | ☑ | ☑ | ☑ | ☑ |

|

1 1/2" | ☑ | ☑ | ☑ | ☑ |

|

| 2" | ☑ | ☑ | ☑ |

|

|

| 2 1/2" | ☑ |

|

|

|

|

| Maximum width cm | ||||

| Specification List of Crimped Wire Mesh(Partly) | |||

Wire Diameter mm | Mesh | Wire Diameter mm | Mesh |

2.0-1.6 | 3 | 1.0-0.6 | 10 |

1.8-1.2 | 3.5 | 0.8-0.5 | 12 |

1.6-0.7 | 4 | 0.7-0.5 | 14 |

1.6-0.6 | 5 | 0.60-0.4 | 16 |

1.5-0.8 | 6 | 0.6-0.4 | 18 |

1.2-0.7 | 8 | 0.5-0.35 | 20 |

1.5 | 10 | 1.9 | 20 |

1.6 | 10 | 2.0 | 20 |

1.5 | 12 | 1.9 | 25 |

1.6 | 12 | 2.0 | 25 |

1.5 | 15 | 2.5 | 20 |

1.6 | 15 | 2.6 | 20 |

1.9 | 10 | 2.5 | 25 |

2.0 | 10 | 2.6 | 25 |

1.9 | 12 | 2.5 | 30 |

2.0 | 12 | 2.6 | 30 |

1.9 | 15 | 3.0 | 25 |

2.0 | 15 | 3.2 | 25 |

1.9 | 18 | 3.0 | 30 |

2.0 | 18 | 3.2 | 30 |

4.0 | 19×9 | 1.2 | 5.5×1.5 |

3.5 | 18×8 | 1.0 | 4.5×1.2 |

3.2 | 16×7 | 0.8 | 4.0×1.0 |

2.9 | 15×6 | 0.7 | 3.5×0.9 |

2.6 | 13.5×5 | 0.7 | 3.3×0.8 |

2.3 | 11.5×4 | 0.6 | 3.0×0.7 |

2.0 | 10×3.5 | 0.5 | 2.7×0.6 |

1.8 | 9×3 | 0.5 | 2.3×0.5 |

1.6 | 8×2.5 | 0.4 | 1.9×0.4 |

1.4 | 7×2 | 0.3 | 1.5×0.3 |