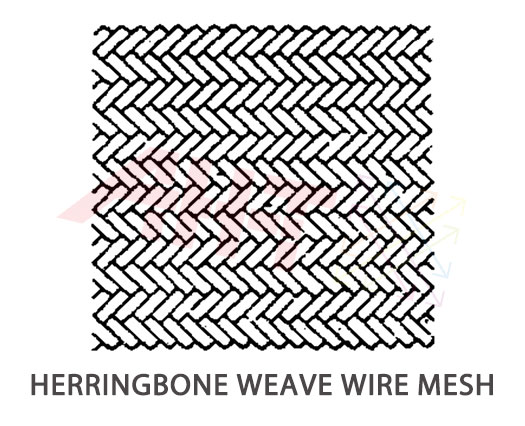

Herringbone Weave Wire Mesh

The herringbone woven wire mesh is also known as broken twill weaving, and it is a unique V-shaped weaving pattern, commonly found in twill metal wire mesh. It is called "zigzag pattern" because it resembles the bones of a herring. The direction of the twill fabric will reverse every 20, 50, 100, 200, 500 milimeters depending on the width and specific application, forming a similar herringbone-like framework. Its surface is smooth and durable, corrosion-resistant, has high tensile strength, and is not prone to deformation. It is commonly used as an accessory in industries such as food, petrochemicals, electronic components, mechanical parts, heat treatment, etc.

Herringbone Weave Wire Mesh Features and Advantages

The mesh of the herringbone weave wire mesh is fine, which can effectively prevent the leakage of fine particles, and is suitable for the filtration and screening of fine particles.

Herringbone weave wire mesh is smooth to ensure the stability of the conveying process, suitable for screening and filtering fine particles and unstable items.

Its weaving method is unique, it has a strong load-bearing capacity. Not only is it not easy to deform, but also capable of carrying heavy loads.

The mesh belt is firm, high tensile strength, not easy to deformation, suitable for high-temperature operations and stamping operations.

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;Different metal materials can be customized according to customer needs.

Herringbone Weave Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom herringbone weave wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of herringbone weave wire mesh customization, has reached a strategic partnership with more than 60 countries in the world, Welcome to inquiry and request samples.

Herringbone Weave Wire Mesh Quality Control

Authorized Economic operator

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Herringbone Weave Wire Mesh Applications

Herringbone wire mesh is widely used in a variety of industrial and architectural applications, including:

Filtration: Used in oil and gas, water treatment, and air filtration systems.Herringbone weave wire mesh is a versatile and durable option or industrial and architectural applications, with its distinct herringbone pattern, this type of wire mesh provides excellent strength and durability, making it perfect for a wide range of applications.

Herringbone Weave Wire Mesh Specifications

| AHT/Hatong Herringbone weave wire Mesh of Specification | ||||

Mesh per inch | Wire diameter | Aperture(mm) | Open Area | Weight |

warp*weft | (mm) | warp*weft | % | kg/sqm |

40*40 | 0.190 | 0.440*0.440 | 49.1 | 0.707 |

Wire Diameter(mm) | Mesh/Inch | Aperture (mm) |

0.65 | 10 | 1.89 |

0.71 | 8 | 2.47 |

0.50 | 14 | 1.31 |

0.60 | 12 | 1.52 |

0.40 | 20 | 0.87 |

0.40 | 16 | 1.19 |

0.30 | 30 | 0.55 |

0.35 | 24 | 0.71 |

0.20 | 50 | 0.31 |

0.25 | 40 | 0.39 |

0.135 | 80x70 |

|

0.17 | 60 | 0.25 |

0.11 | 100x90 | — |