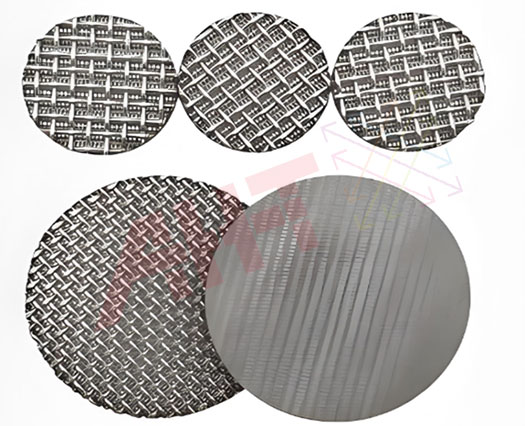

Five Layer Sintered Mesh

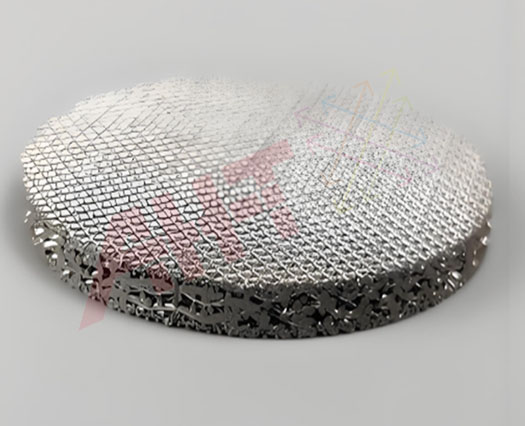

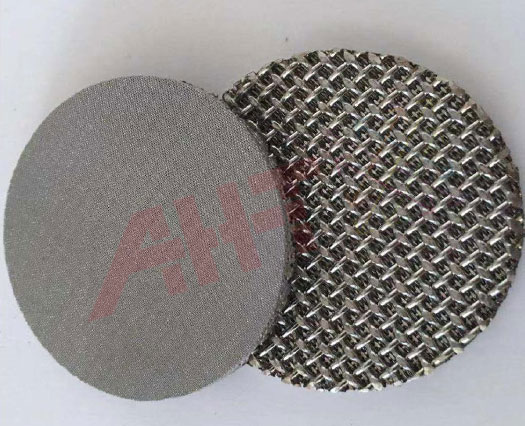

The five-layer sintered wire mesh is made through the sintering process, consisting of a multi-porous product made of five layers of stainless steel wire mesh. This process involves pressing and vacuum sintering the five layers of stainless steel wire mesh together in a special stacking manner to achieve permanent adhesion. It is the most widely used standard combination. Compared to new filtering materials with higher mechanical strength and overall rigidity, the five-layer sintered wire mesh is more suitable for forming, cutting, welding and stamping, and can be processed into metal filter cores in shapes such as circular, cylindrical, conical, and pleated. The metal film can effectively replace filter cloth or single-layer woven wire mesh. The five-layer sintered mesh has uniform pore size, is not prone to deformation, has stable filtration accuracy, is easy to clean, and is therefore widely used in industries such as chemical, petroleum, pharmaceutical, etc.

High filtration accuracy

The five-layer sintered mesh has a very stable filtration accuracy, which can effectively remove small particles, suspended matter and impurities in liquid or gas, and the filtration size can play a uniform surface filtration performance in the range of 2-200μm;

Standard material of three-layer sintered mesh: S304(AISI304), S316(AISI316), S316L(AISI316L);

Other metal materials: Hastelloy alloy, Monel, Inconel, etc.Different metal materials can be customized according to customer needs.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom five-layer sintered mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of five-layer sintered mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System CertificationAuthorized Economic operator

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Five-layer sintered mesh is widely used in petrochemical industry, metallurgical machinery, energy and environmental protection, textile power, aerospace, medicine and other industrial fields.

Five Layer Sintered Mesh Specifications

| AHT/Hatong Five Layer Sintered Mesh of Specification | ||||||||

Nominal filtration accuracy(μm) | Protective layer | Filter layer | Separating layer | Reinforcing layer | Reinforcing layer | Air permeability (L/min/cm2) | Bubble point pressure (Pa) | Porosity (%) |

1 | 100 | 400×3000 | 100 | 12×64 | 64×12 | 1.81 | 360-600 | About 40% |

2 | 100 | 325×2300 | 100 | 12×64 | 64×12 | 2.35 | 300-590 | |

5 | 100 | 200×1400 | 100 | 12×64 | 64×12 | 2.42 | 260-550 | |

10 | 100 | 165×1400 | 100 | 12×64 | 64×12 | 3 | 220-500 | |

15 | 100 | 165×1200 | 100 | 12×64 | 64×12 | 3.41 | 200-480 | |

20 | 100 | 165×800 | 100 | 12×64 | 64×12 | 4.5 | 170-450 | |

25 | 100 | 165×600 | 100 | 12×64 | 64×12 | 6.12 | 150-410 | |

30 | 100 | 400 | 100 | 12×64 | 64×12 | 6.86 | 120-390 | |

40 | 100 | 325 | 100 | 12×64 | 64×12 | 7.1 | 100-350 | |

50 | 100 | 250 | 100 | 12×64 | 64×12 | 8.41 | 90-300 | |

75 | 100 | 200 | 100 | 12×64 | 64×12 | 8.7 | 80-250 | |

100 | 100 | 150 | 100 | 12×64 | 64×12 | 9.1 | 70-190 | |