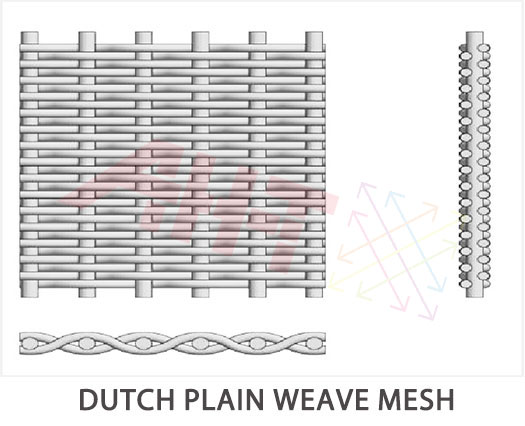

Dutch Weave Wire Mesh

Dutch wire mesh is made of relatively thick wire for warp threads and fine wire for weft threads. The weft threads alternate between the upper and lower warp threads, forming a fine mesh in one direction and a coarse mesh in the other direction, with tightly woven mesh holes shaped like cones or wedges. This weaving method has very fine mesh holes and higher strength, and is mainly used as filter cloth. The shape and position of the mesh holes as well as the particle retention rate can be improved, and it is conducive to forming a filter cake. It is widely used in fuel filters, precision pressure filters, vacuum filters, and is also applicable to industries such as petroleum, chemical engineering, rubber, plastics, tire manufacturing, metallurgy, aerospace, chemical fibers, and food.

Dutch Weave Wire Mesh Features and Advantages

Super load capacity

Dutch weave wire mesh because of its high structural density, small mesh, small plane deformation during use, has a strong load capacity, good mechanical strength and toughness;

High filtration accuracy

The dutch weave wire mesh has high filtration accuracy, fast flow rate, and can filter the particle size between 0.02mm and 23mm;

Long service life

Dutch weave wire mesh has anti-corrosion, anti-rust, anti-tear, wear-resistant and other characteristics, long service life, do not need to be replaced often;

Good light transmission

The dutch weave wire mesh has good light transmission, can prevent ultraviolet radiation, and has a good protective effect.

Dutch Weave Wire Mesh Available Material

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;

Epoxy Coated Wire Mesh: Stainless steel, aluminum alloy, carbon steel;

Monel wire Mesh: 400;

Nickel wire Mesh: 200;

Low carbon steel wire mesh: C1008;

Different metal materials can be customized according to customer needs.

Dutch Weave Wire Mesh Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom dutch weave wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of dutch weave wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Dutch Weave Wire Mesh Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Dutch Weave Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Dutch Weave Wire Mesh Applications

| AHT/Hatong Dutch Weave Wire Mesh of Specification | |||

Mesh count | Wire diameter inches | Absolute filter rating | Nominal filter rating microns |

8×85 | .014 × .016 | 318-340 | 250-255 |

12×64 | .024×.0165 | 270-285 | 200-205 |

14×88 | .020×.013 | 225-245 | 150-155 |

20×150 | .0098×.007 | 155-165 | 100-105 |

24×110 | .015×.010 | 115-125 | 80-85 |

30×150 | .009×.007 | 95-100 | 65-70 |

40×200 | .007×.0055 | 65-70 | 55-60 |

50×250 | .0055×.0045 | 55-60 | 40-45 |

80×400 | .0049×.0028 | 43-48 | 35-40 |

20×250 | .0098×.0079 | 110-120 | 98-105 |

30×360 | .0098×.0060 | 90-100 | 80-84 |

40×560 | .0070×.0040 | 70-75 | 47-52 |

80×700 | .0040×.0030 | 35-40 | 24-26 |

200×600 | .0024×.0018 | 28-32 | 19-21 |

165×800 | .0028×.0020 | 24-26 | 14-16 |

165×1400 | .0028×.0016 | 16-18 | 9-11 |

200×1400 | .0028×.0016 | 12-14 | 5-6 |

250×1400 | .0022×.0016 | 11-12 | 3-4 |

325×2300 | .0015×.0010 | 8-9 | 2-3 |