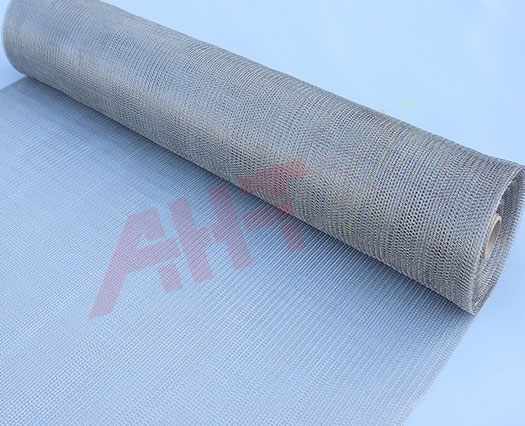

Stainless Steel Knitted Mesh

The stainless steel knitted mesh is also known as Gas-Liquid Filter Demister, Shielding Metal Mesh. It is made of stainless steel wires and is a knitted mesh in a hooked weaving pattern. The production process involves hooking the stainless steel wires into tubular shapes, then flattening them into continuous strips, rolling them up for packaging, and the mesh surface comes in two types: flat type and corrugated type. Hatong has an independent R&D team, has introduced advanced stainless steel knitted mesh equipment, and has a modern production workshop. It can perform oil-free weaving and has the characteristics of uniform pores and flat net surface. It is widely used in gas and liquid filtration in fields such as petroleum, chemical industry, metallurgy, and pharmaceuticals, as well as EMI shielding in the electronics field.

Clean mesh

Our factory introduces advanced technology, using oil-free weaving, the production of stainless steel knitted mesh has the characteristics of clean mesh and uniform mesh;

Stainless steel contains chromium, which can form an oxide film on the surface to prevent corrosion and resist high-temperature environments;

High-quality stainless steel material, with high pressure resistance, can withstand strong tensile strength;

Stainless steel knitted mesh because of its unique processing technology, so that it has strong and flexible characteristics, easy to cut, bending, stretching and other industrial processing.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom stainless steel knitted mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of stainless steel knitted mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System CertificationInner paper tube & Carton box & Plywood case

Stainless Steel Knitted Mesh Applications

Stainless steel knitted wire mesh are applied to those applications including cryogenic, high temperature, corrosive atmosphere, heat conductive, high usage, or special service applications.

Stainless Steel Knitted Mesh Specifications

AHT/Hatong Stainless Steel Knitted Mesh of Specification | ||||

Specification of Round Wire Knitted Mesh | ||||

Type | Wire Diameter(mm) | Width (mm) | Number of Stitches Per cm on Length | Number of Stitches Per cm Across Lay Flat |

Fine Mesh | 0.08-0.18 | 6-300 | 3.5 | 4.4 |

Medium-Fine Mesh | 0.16 | 40-600 | 2.4 | 3.5 |

Standard Mesh | 0.08-0.35 | 30-1000 | 1.6 | 1.9 |

Coarse Mesh | 0.25-0.40 | 30-1000 | 1.6 | 0.74 |

Super Coarse Mesh | 0.4-0.5 | 100-350 | 0.5 | 0.5 |

Specification of Fat Wire Knitted Mesh | ||||

Wire Diameter (mm) | Mesh Opening/Loop Size(mm) | Number of Needles | Maximum Width (mm) | Minimum Width (mm) |

0.1×0.3 | 2×4 | 36 | 60 | 55 |

0.1×0.3 | 4.5×4,2.5×4 | 34 | 150 | 100 |

0.1×0.4 | 4.5×5.5,2.5×5.5 | 40 | 150 | 120 |

0.1×0.4 | 4×3.5,2.5×3.5 | 56 | 205 | 180 |

0.1×0.4 | 4×4,3×4 | 65 | 260 | 240 |

0.2×0.4 | 5.2×3.5,3×3.5 | 94 | 420 | 380 |

0.2×0.4 | 7.5×5,5×5 | 102 | 565 | 490 |

0.2×0.5 | 5×4,2.5×4 | 128 | 560 | 470 |