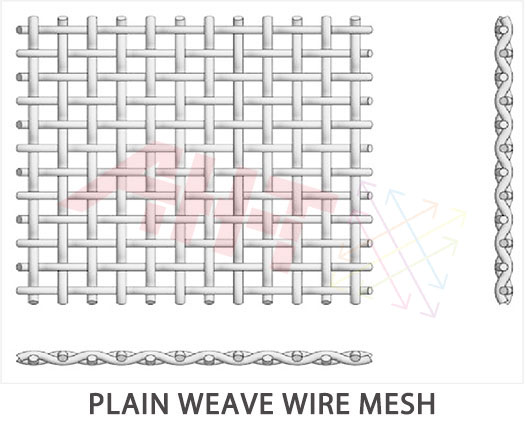

Plain Weave Wire Mesh

Plain weave wire mesh is the most commonly used and simplest type. The plain woven wire mesh of Hatong is woven in such a way that each warp thread (the metal wire parallel to the length direction of the fabric) alternately passes through the warp threads (weft threads or ray threads) on the fabric at a 90-degree angle. It is commonly used in shock absorbers, gas and liquid filtration, noise reduction, sealing and gasket applications, insulation, EMI / RFI shielding, defogging, technical separation, and engine catalysts. It is a frequently used material in various industries such as automobiles, electronics, aviation, military, industry, commercial consumer goods, telecommunications, medical, testing equipment and accessories.

Plain Weave Wire Mesh Features and Advantages

With good air permeability

The plain weave wire mesh produced by our factory has smooth mesh surface, uniform mesh light texture, good air permeability, and can be used for fine filtration in industry.

High temperature and corrosion resistance

Our factory will strictly control the selection of raw materials, select the high-quality raw materials with high temperature resistance, and inspect in the process of production and processing, ensure the application of severe industrial environment.

The warp and weft yams of the plain weave wire mesh are staggered, and the interweaving points are the most, so that it is firm, wear-resistant, stiff and smooth.

Plain wire mesh is widely used to filter and screen particles or liquids in industry, and can also be used as a protective mesh, isolation mesh and decorative mesh for construction projects.

Stainless Steel Wire Mesh: 304, 304L, 316, 316L, 310, 310S, 314, 321, etc.

Brass Wire Mesh: Copper65%, Zinc35%;Different metal materials can be customized according to customer needs.

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom plain weave wire mesh manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of plain weave wire mesh customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Authorized Economic operator

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Plain Weave Wire Mesh Applications

Plain weave wire mesh can be used in many applications such as a vibration & shock absorber, gas & liquid filtration, noise dampening, seal & gasket applications, heat insulation, EMI / RFI shielding, mist elimination & technology separation and engine catalyst etc. It is widely used in various industries such as automobile, electronics, aviation, military, industrial, commercial consumer goods, telecommunication, medical, test equipment and accessories, etc.

| AHT/Hatong Plain Weave Wire Mesh of Specification | |||||

Mash per | Wire diameter | Width of opening | Open area | ||

Inches | mm | Inches | mm | percen | |

1×1 | .157 | 4.0 | 84 | 21.4 | 71.0 |

4×4 | .063 | 1.6 | 187 | 4.75 | 56.0 |

8×8 | .043 | 1.1 | 08 | 2.00 | 42.0 |

10×10 | .039 | 1.0 | 06 | 1.54 | 36.0 |

12×12 | .023 | 584 | 060 | 1.52 | 51.8 |

14×14 | .023 | 584 | 048 | 1.22 | 45.2 |

16×16 | .018 | 457 | 0445 | 1.13 | 50.7 |

18×18 | .017 | 432 | 0386 | 98 | 48.3 |

20×20 | .016 | 406 | 0340 | 86 | 46.2 |

24×24 | .014 | 356 | 0277 | 70 | 44.2 |

30×30 | .012 | 305 | 0213 | 54 | 40.8 |

35×35 | .011 | 279 | 0176 | 45 | 37.9 |

40×40 | .010 | 254 | 0150 | 38 | 36.0 |

50×50 | .008 | 203 | 0120 | 31 | 36.0 |

60×60 | .0075 | .191 | .0092 | .23 | 30.5 |

70×70 | .0065 | .165 | .0078 | 20 | 29.8 |

80×80 | .0055 | .140 | .0070 | .16 | 31.4 |

100×100 | .0045 | .114 | .0055 | .14 | 30.3 |

120×120 | .0037 | .0940 | .0048 | 11.55 | 30.7 |

150×150 | .0026 | .0660 | .0041 | .1041 | 37.4 |

180×180 | .0023 | .0584 | .0033 | .0838 | 34.7 |

200×200 | .0021 | .0533 | .0029 | .0737 | 33.6 |

250×250 | .0016 | .0406 | .0024 | .0610 | 36.0 |

300×300 | .0015 | .0381 | .0018 | .0457 | 29.7 |

325×325 | .0014 | .0356 | .0017 | .0432 | 30.0 |

400×400 | .0010 | .0254 | .0015 | .0370 | 36.0 |

500×500 | .0010 | .0254 | .0010 | .0254 | 25.0 |

635×635 | .008 | .0203 | .0008 | .0203 | 25.0 |