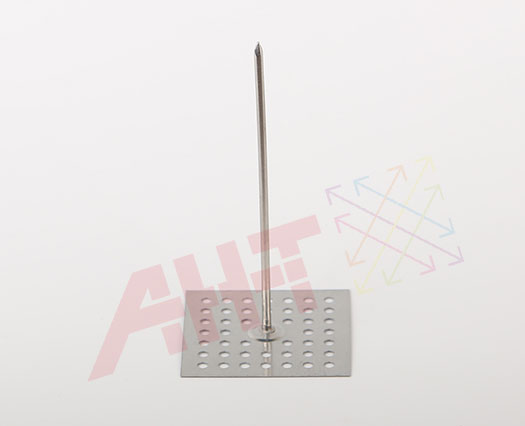

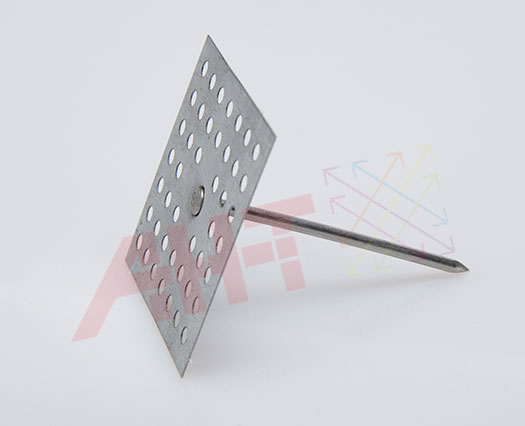

Perforated Pin

The perforated pin is an insulating bracket, consisting of a perforated metal base (1.5 inches x 1.5 inches or 2 inches x 2inches) and pins (12GA steel wire). It is used to fix the insulation layer and is used in conjunction with a self-locking washer. The larger base is designed to enhance the bonding strength by expanding the bonding area, and these perforations enable it to firmly fix the anchor bolts in place using liquid adhesives. Hatong uses an automated production method to manufacture the perforated pins, with strong production capacity and stable product quality. The excellent stamping mold design and production process ensure that these pins are perfectly perpendicular to the base, firmly riveted, and have no burs at the edges. It is a device specifically used to fix insulation foam or other materials such as rock wool, mineral wool, glass wool, ceramic wool, phenolic foam, etc, on the surfaces of metals, woods, concrete, composite materials, or other common building materials.

Perforated Pin Features and Advantages

Easy to install

The perforated pin is composed of a pin and a perforated metal base. It has a compact structure, is lightweight, is easy to assemble and install;

Resistant to wear and tear

The larger perforated base of the perforated pin has a larger friction area, resulting in uniform wear. It exhibits excellent wear resistance under low-frequency vibration or static loads.

Low cost

The production process of the perforated pin is simple, with low cost and short assembly time. It is suitable for mass production.

Wide applicability

The perforated pins can connect components of different materials and shapes, and are used in various application fields.

Perforated Pin Production Capacity

AHT/ Hebei Hatong Wire Mesh Co., Ltd. is a professional design, research and development, production, custom perforated pin manufacturer, and our plant covers an area of 40000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of perforated pin customization, has reached a strategic partnership with more than 60 countries in the world. Welcome to inquiry and request samples.

Perforated Pin Quality Control

AHT/ Hebei Hatong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic operator

Perforated Pin Packaging

Carton box & Plywood case

Perforated Pin Applications

It is widely used in various industrial applications, with its customizable specifications and easy-to-install nature, perforated pin is an excellent choice for joining multiple components together.

Perforated pins are used in various applications, including:

Automotive Industry

Perforated pins are commonly used in automotive manufacturing for assembling various components, including suspension systems, steering mechanisms, and braking systems.

Construction industry

Perforated pins are used in the construction industry for assembling various components, including steel structures, precast concrete panels, and HVAC systems.

Manufacturing industry

Perforated pins are used in various manufacturing processes, including welding, grinding, and stamping, for securing parts together.

Perforated Pin Specifications

AHT/Hatong Perforated Pin of Specification | |

Material of Perforated Pin | |

Standard Material | Low carbon steel, Aluminum or Stainless steel |

Plating | Galvanized coating or copper plated 0.08-0.18 |

Self-locking Washer | Available in all kind of sizes, shapes, materials |

Size of Perforated Pin | |

Perforated base | 1.5"×1.5", 2"×2" |

Pin diameter | 12GA(0.105") |

Length | 1"1-5/8" 2" 2-1/2" 3-1/2" 4-1/2" 5-1/2" 6-1/2" etc. |